Stanbee Calibration Tool app for iPhone and iPad

Developer: Stanbee Company Inc.

First release : 24 Mar 2019

App size: 96.55 Mb

The Stanbee Calibration Tool enables workers on the factory floor to self-test equipment without the assistance of a Stanbee technician. Factories will be supplied with the app as well as the appropriate testing tools, an infrared scanner and/or a thermocouple thermometer with probe.

Because the activation process has two parts — heating the materials to the proper temperature to mold it to the shoe, and cooling the material to fix the shape — the app includes both hot and cold tests.

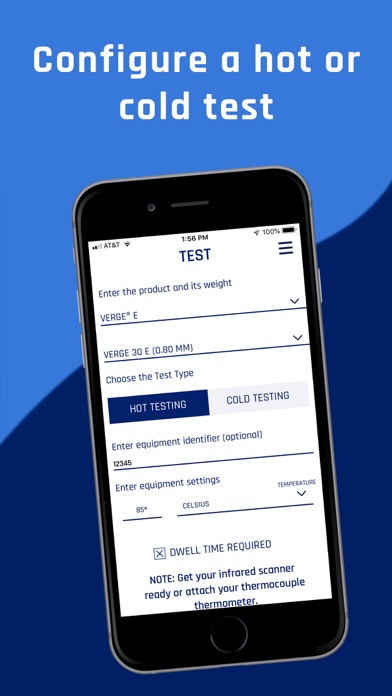

Both types of test follow the same process: users input the particulars of their configuration which include the Stanbee product type and thickness, model of the shoe, and an identifier for the activation machine. The app displays the recommended temperature and users then enter the current settings of the machine.

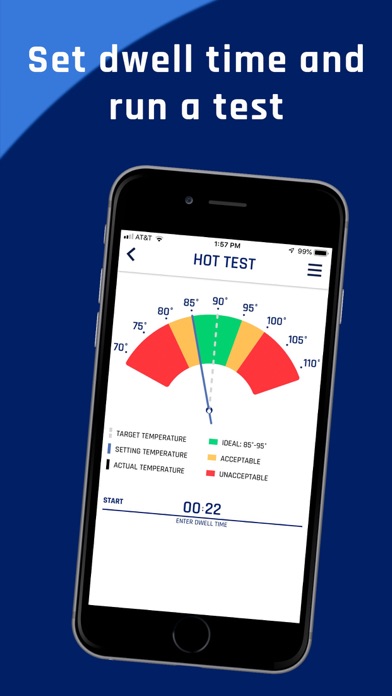

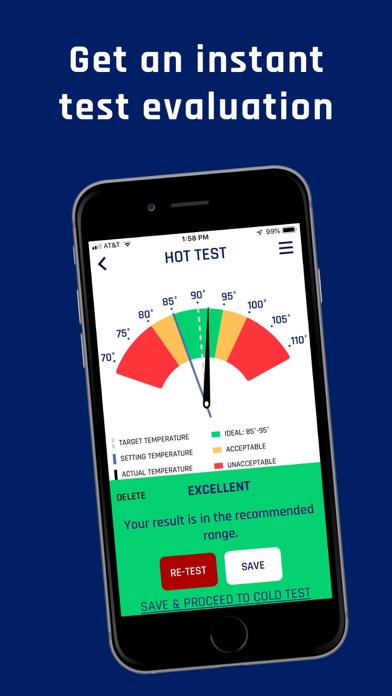

The testing of the actual equipment temperatures with the temperature measurement tools comes next, supported by the app’s timer which records the dwell time needed to reach the optimal temperature. The user then inputs the results from the machines display panel and the app generates an evaluation, plotting the results against the settings and the desired ranges with an easy to interpret visual gauge display.

The results are saved in list form and the app generates a graph that provides a simple trending analysis.

The app also features short instructional videos that illustrate each step of the shoe part activation process, as well as specification sheets for each of the Stanbee products.